A PA mini electric hoist is widely used for lifting and material handling in workshops, warehouses, construction sites, and daily maintenance work. The difference between “standard” and “reliable” often comes down to how the key components are made and how strictly each unit is tested before shipment. The typical production process includes motor preparation, machining, assembly, and packaging.

Below is an overview of how we build our PA mini electric hoists with consistent quality and stable performance.

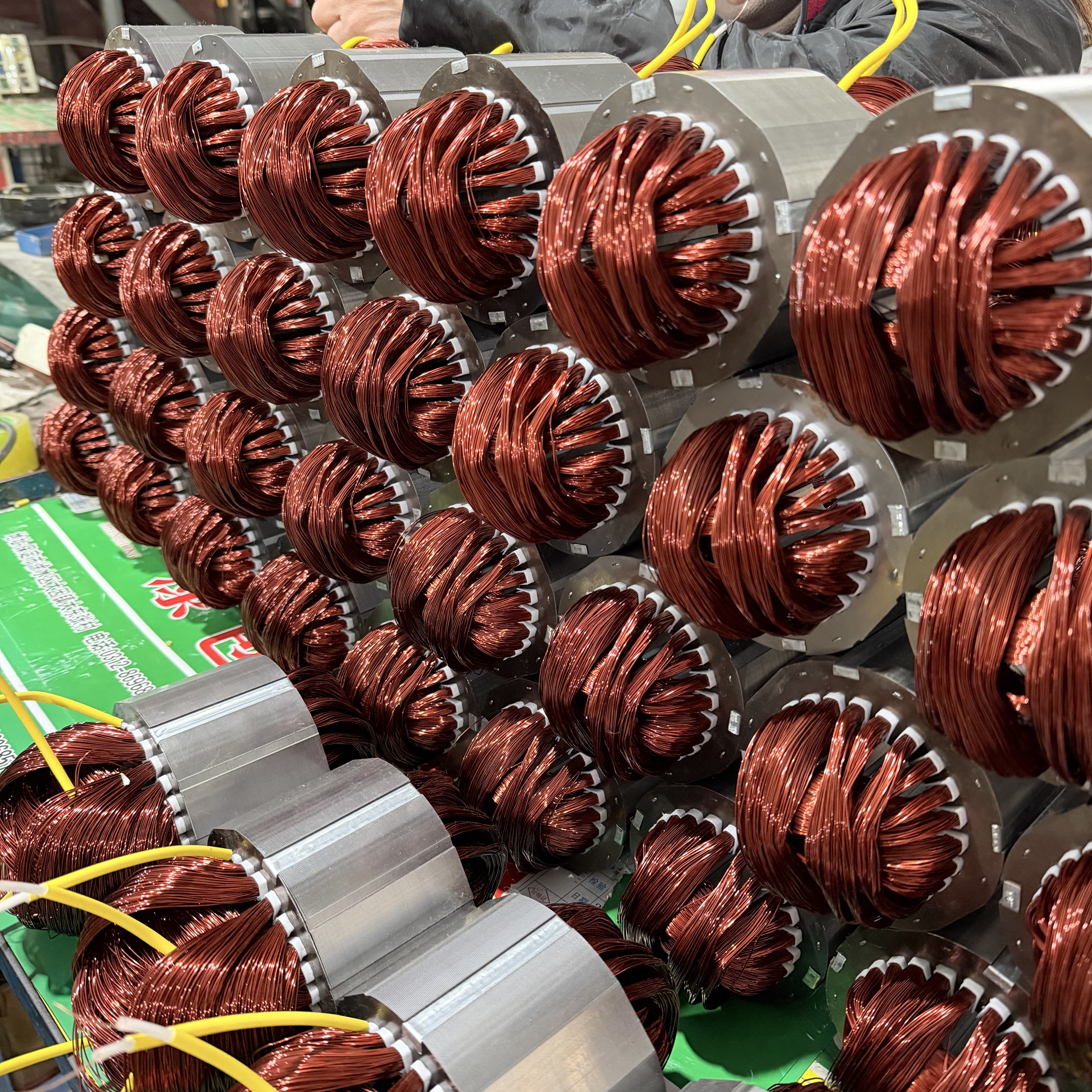

The motor is the heart of a mini electric hoist, so quality starts here. In production, the copper winding and motor assembly must be controlled carefully, and motors are typically tested before moving to final assembly.

For our hoists, we use QZY-2/180 100% pure copper motor winding and an enlarged rotor design to support stable output, improved heat dissipation, and longer service life—especially under frequent lifting cycles.

Precision machining ensures the hoist body, gear housing, shafts, and mounting interfaces fit correctly. Many manufacturers rely on CNC punching, drilling, cutting, and grinding to keep dimensional accuracy consistent.

3) Assembly: From Frame to Wire Rope Drum

Once key parts are ready, the hoist is assembled on a production line—typically including the frame, motor and gear set, shaft system, wire rope drum, pendant control, and cables.

At this stage, we also integrate safety and usability features such as emergency stop, limit protection, and reinforced hook configurations.

Before packing, every unit should be verified for real working conditions. In addition to motor checks, we conduct complete functional tests to confirm performance and safety consistency.

After testing, products are packed for export. For international customers, we support OEM/ODM customization including:

Voltage options

Wire rope length

Product color and branding

Packaging requirements for different markets

If you are sourcing PA mini electric hoists (PA200–PA1200) for distribution or projects, we can recommend best-selling configurations and provide OEM support based on your market needs.

Name: Zoe Liu

Mobile:+86 13932282895

Tel:+86 13932282895

Whatsapp:8613932282895

Email:info@hangchenghoist.com

Add:Southwest of Weigezhuang Village, Donglu Township, Qingyuan District, Baoding City, Hebei Province, China